In any power distribution system, there is some risk of faults, which can lead to phase-to-ground arcing, phase-to-phase arcing, and downed conductors. These arcs and energized downed conductors are common sources of ignition and can result in devastating wildfires. Utility companies use tree wire and spacer systems to mitigate these risks. AerialGuard® Cable Systems enhance the effectiveness of covered conductors in reducing fire risk, especially in densely forested areas.

American Wire Group is proud to offer AerialGuard® Cable Systems, the perfect solution for your tree wire and spacer cable needs. AerialGuard® tree wire and spacer cables are made from the highest quality materials and are designed to provide superior strength and durability while being easy to install and maintain.

In case of incidental contact with wildlife or trees, the outer layer prevents short circuits and temporary faults. With various sizes and configurations available, AerialGuard® cable deliver reliable performance for a wide range of applications.

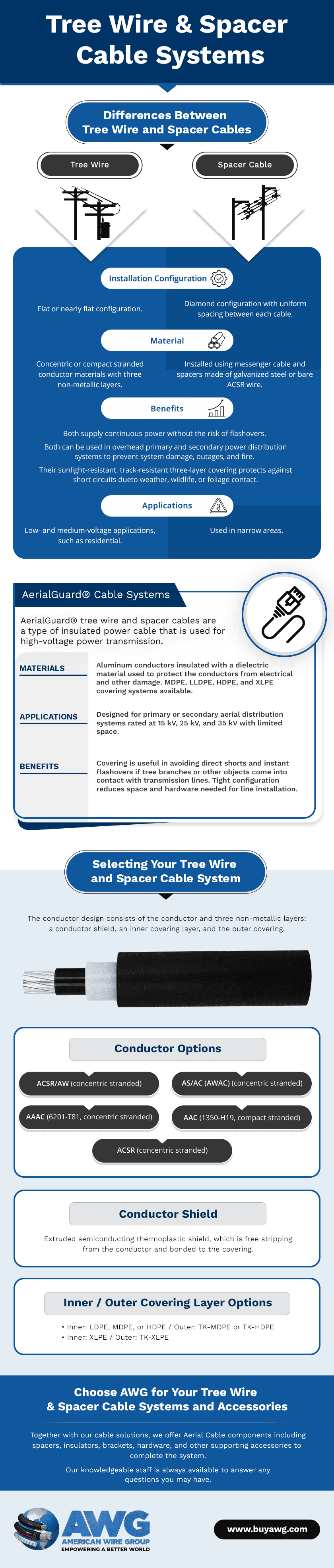

Introduction to Tree Wire and Spacer Cable Systems

Tree wire power cables are usually installed in a flat or nearly flat configuration, with similar spacing as other covered or bare aerial conductors but with a narrower right of way. Tree wire cables are made of concentric or compact stranded conductor materials with three non-metallic layers.

Spacer cable power systems are installed in a diamond configuration using spacer hardware, with uniform spacing between each cable. The cable assembly and spacers are supported by a bare messenger cable made of galvanized steel or bare ACSR wire. Spacer cable systems take up the least amount of space, so they have the narrowest right of way.